- What Is Kanban?

- What Is a Kanban System?

- What Is a Kanban Board?

- Kanban Board Template

- Kanban Card Template

- Kanban System Examples

- Kanban Principles

- Kanban Practices

- Kanban Metrics

- What Is Kanban Software?

- Must-Have Kanban Software Features

- How to Use ProjectManager to Implement the Kanban Methodology

- Benefits of Kanban

- History of the Kanban Methodology

- Kanban Training, Courses & Certifications

- Kanban FAQs

What Is Kanban? The Kanban Methodology Explained

Kanban is a project management methodology that allows project managers to visualize their team’s work on easy-to-use boards that facilitate the process of planning, scheduling and tracking work.

By using the kanban method, project managers have full transparency in the task management process. The kanban methodology consists of kanban boards, kanban cards, principles and practices. It’s typically used to manage manufacturing and software development projects.

However, the kanban framework can be used in almost all industries. The flexibility of kanban boards makes it easy to customize them. They’re used to track the workflow stages in various fields, such as manufacturing, construction, product development, marketing and more. Here are some of the main uses for the kanban model in businesses and non-profit organizations.

- Task management and workflow automation

- Business process management

- Inventory management

- Operations management

- Production planning

In this guide, we’ll explain the principles, practices and benefits of implementing the kanban methodology in your organization. Among other things, there are kanban board examples and a kanban board template that can be downloaded for free.

ProjectManager is a kanban tool that does all this and more. Build automated workflows for your kanban processes and even work in different views. Build plans with Gantt, then execute in kanban boards and track with dashboards. It’s an all-in-one powerful project and work management software. Get started for free.

While most people just think of kanban boards when they hear the word “kanban”, they’re just one of the components that you’ll need to build a kanban system for your organization. There are other principles, practices and tools that you’ll need to use to successfully implement the kanban methodology in your organization.

What Is a Kanban System?

A kanban system is defined as the framework that organizations use for the practical application of the kanban methodology. A kanban system might use either analog or software tools to help project managers create kanban boards.

A kanban system can take many shapes and forms depending on the industry or organization, but in general terms, a kanban system should at least incorporate some of the following elements.

- Kanban boards and cards

- Kanban principles

- Kanban practices

- Kanban metrics

- Kanban software

Kanban software is the most important component of any kanban system. It is a tool that managers and their teams use to manage projects.

Related: Best Kanban Software of 2024: Top 10 Free & Paid Kanban Tools

Kanban software takes the basic visual approach of a kanban board and cards and digitizes it so the whole team can see the workflow. It makes organization easier and helps project managers and teams manage the workflow better.

But before we dive into the benefits of using kanban software, let’s define what a kanban board is, how it works and what are its different components.

What Is a Kanban Board?

A kanban board is a project management tool that can be used to manage tasks and workflows, which utilizes an analog or digital board with two main components known as kanban columns and kanban cards. The kanban cards represent tasks, and the columns organize those tasks by their progress or current stage in development.

Kanban boards help establish a kanban system for implementing the kanban methodology in an organization, which helps manage workflows, allocate resources, track project progress, and, in so doing, improves team productivity.

Kanban Columns

As noted, columns reside on the board and are a way to break up the different stages of a process or workflow. Kanban cards are organized under the column headings and dragged to the next column to the right to indicate where in the production cycle or workflow they are.

Kanban Cards

Kanban cards live on the kanban board. Each one represents an individual task, also referred to as work items. Each kanban card includes information related to that task, such as its name and a short description. They’ll also be assigned to the team member or members, who will be responsible for executing the task by the deadline.

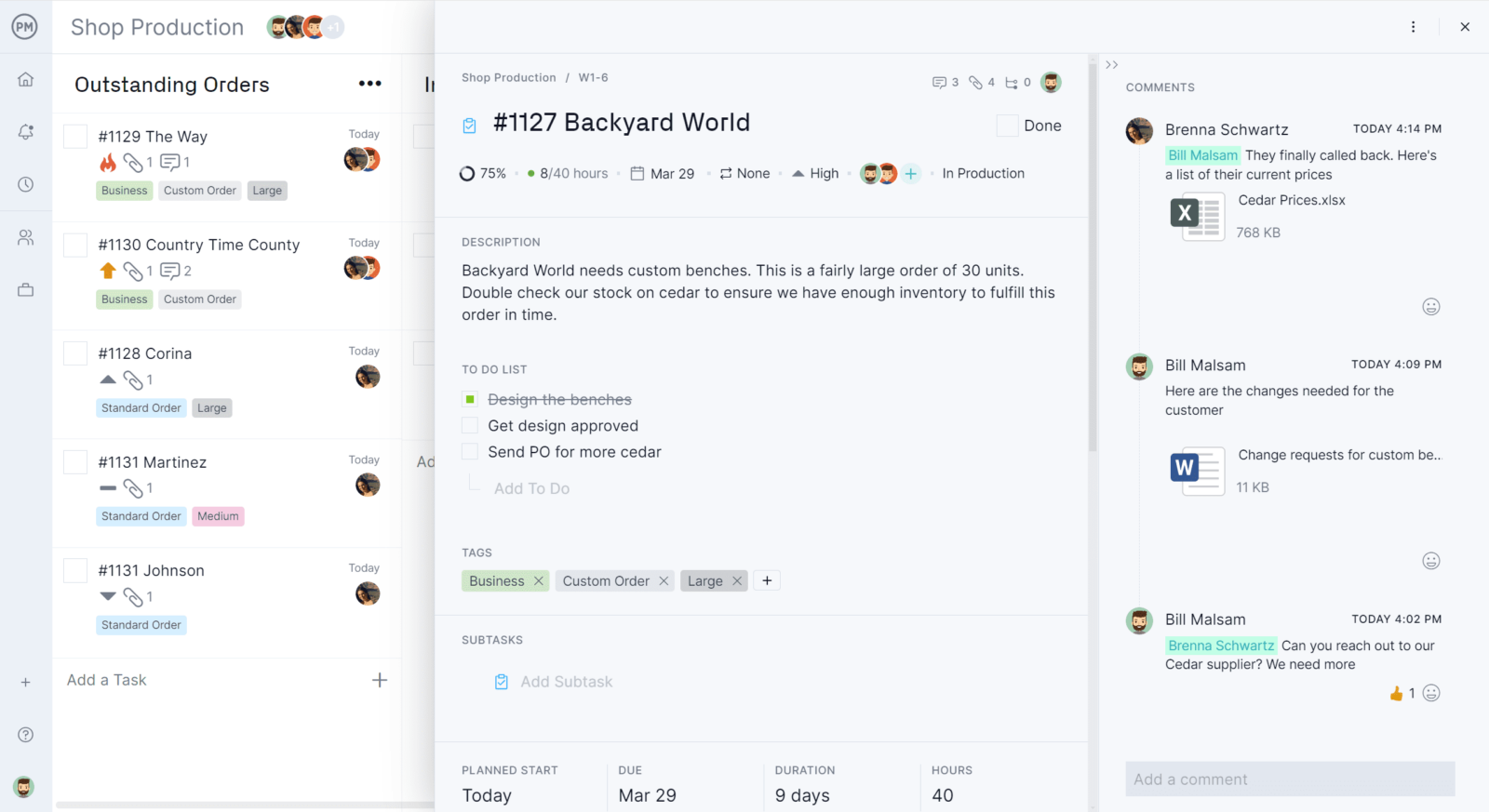

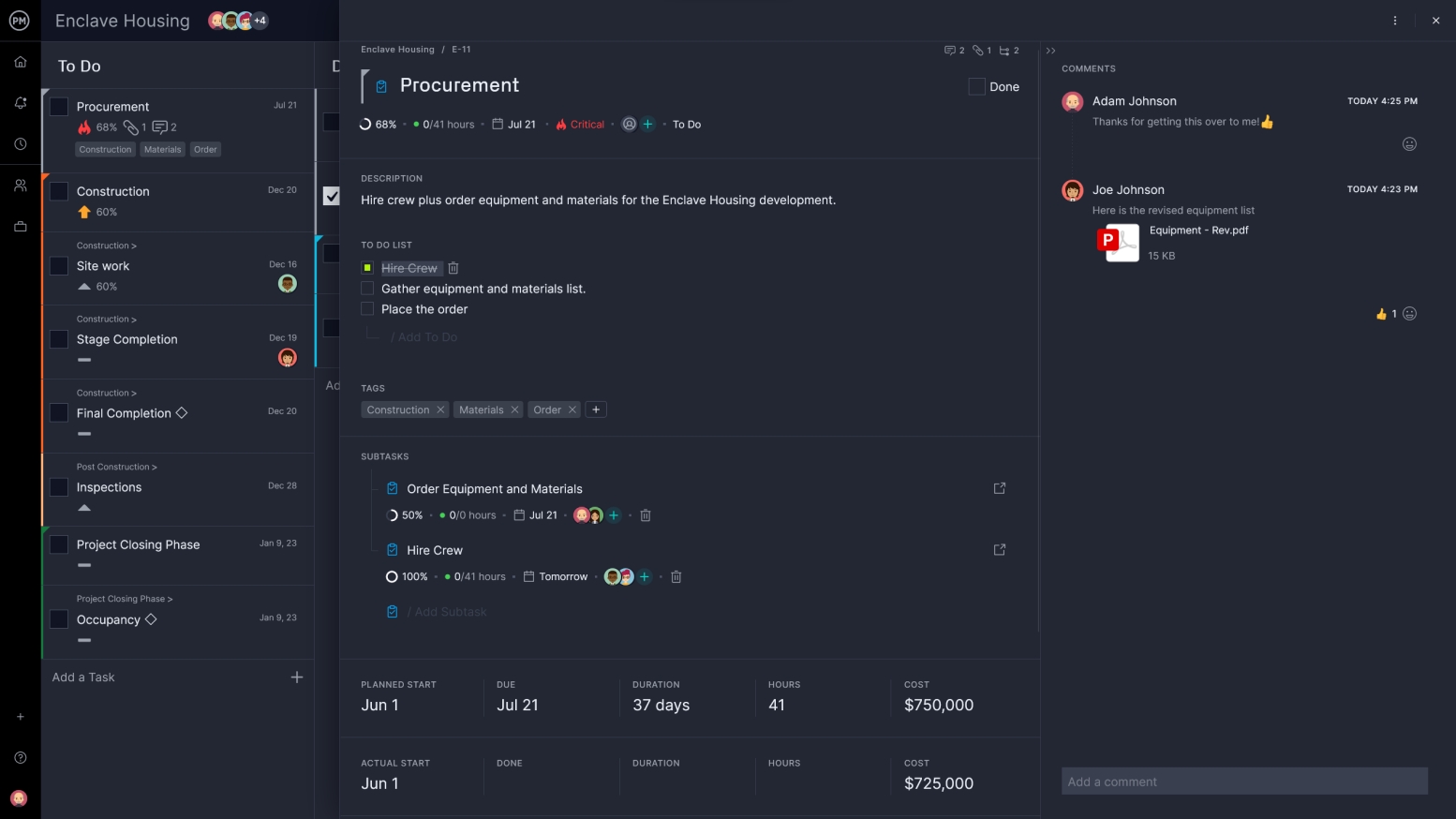

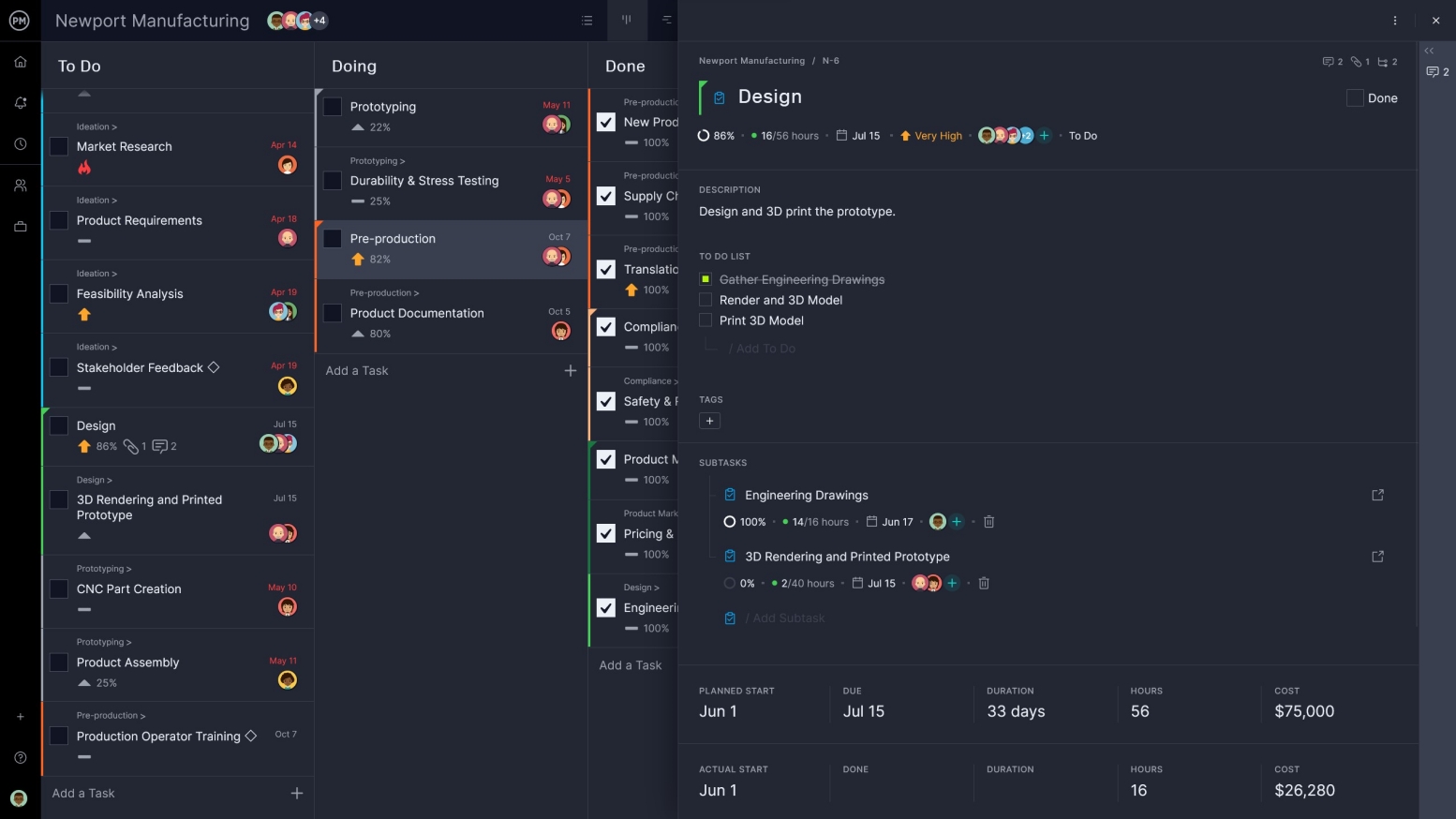

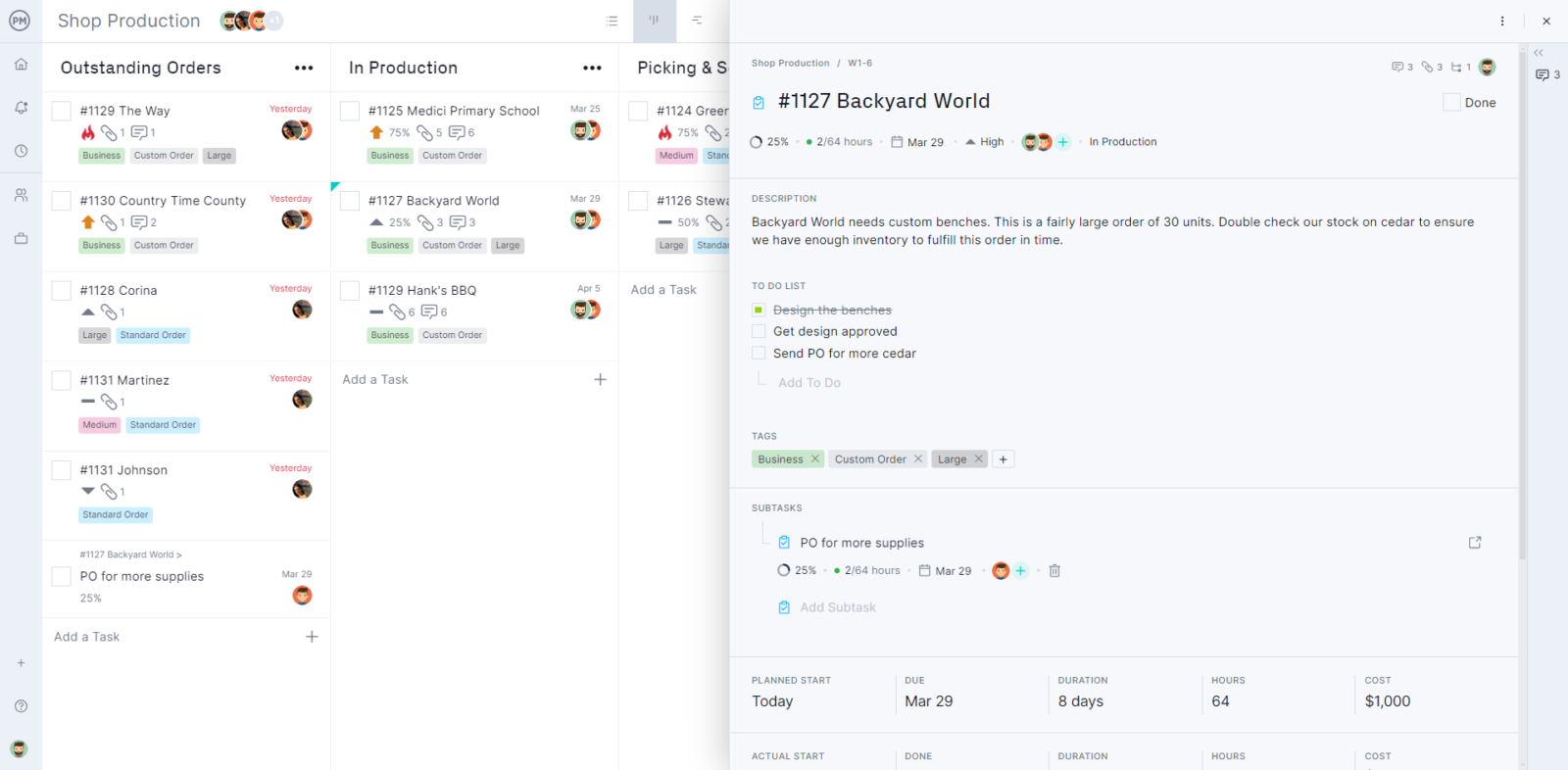

Not all kanban cards are the same. Their features vary from one kanban software to another. Here’s a kanban card example created with ProjectManager.

ProjectManager’s kanban cards show detailed information about project tasks including:

- Description

- Tags

- Due dates

- Priority level

- Percentage of completion

- Estimated vs. actual costs

- Estimated vs. actual task duration

- Assignees

- Task recurrence

- Subtasks

- Comments & file attachments

The kanban board represents the overall project plan and is usually broken into three columns: to do, in progress and done. Kanban cards represent each task in your project, and they’re placed in one of those columns to track their progress and completion.

The beauty of the kanban board is its simplicity and ability to portray the project practically. Each column is a stage in the completion of project tasks, so the board gives teams and project managers an overview at a glance. Teams can see what they’re assigned to work on, and managers can track progress.

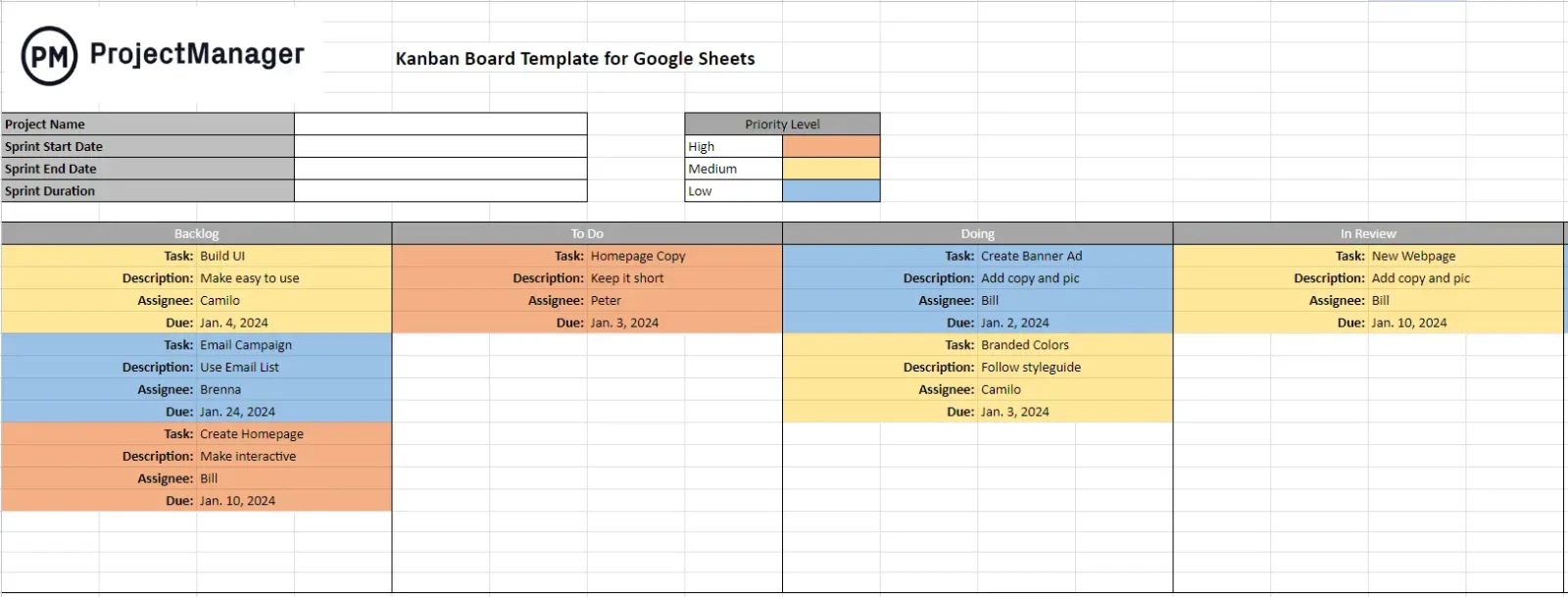

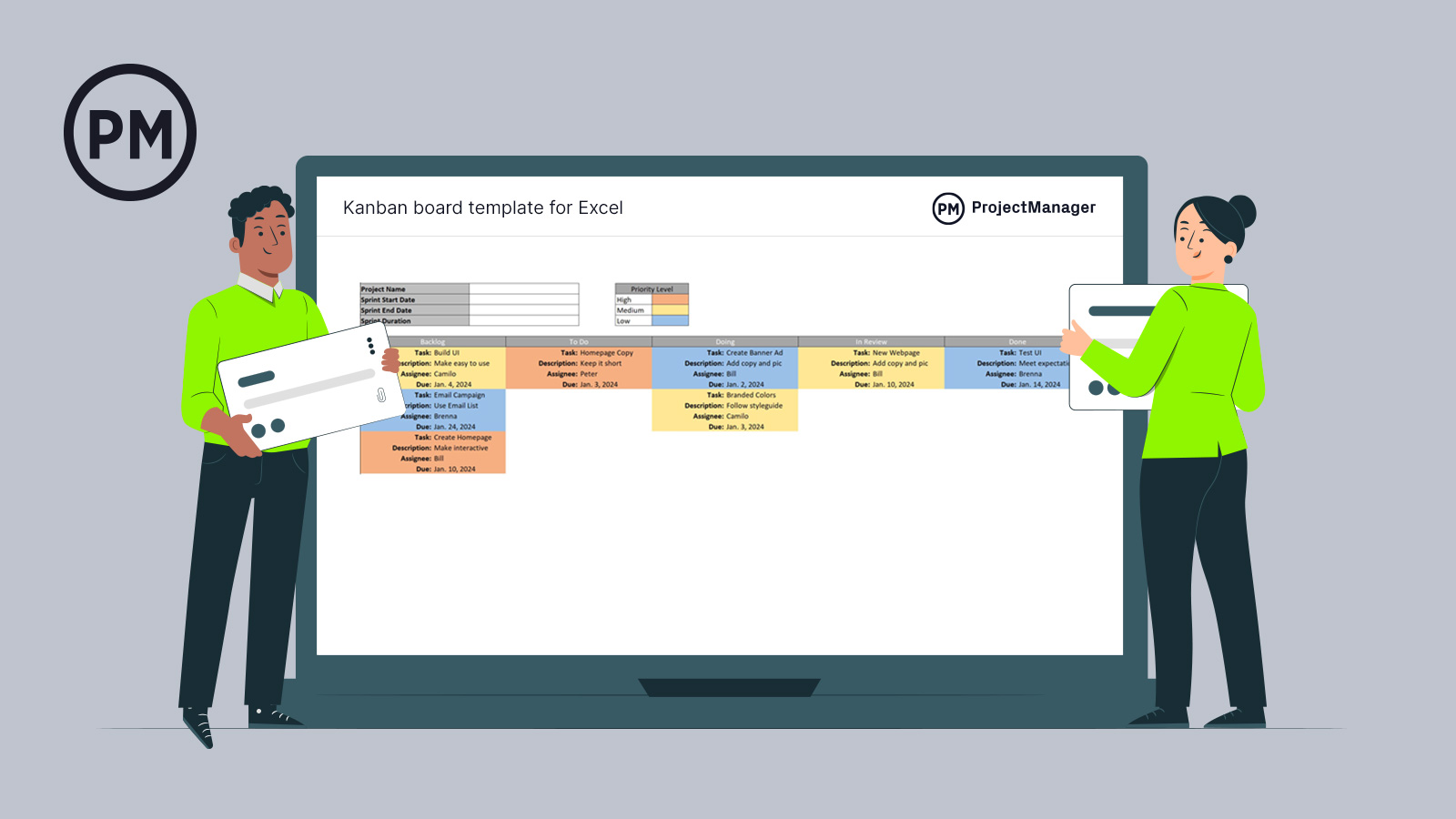

Kanban Board Template

This free kanban board Excel template is a good tool for teams that are getting started with the kanban methodology. While it lacks many features found in kanban software, it can still create columns to represent the stages of a team’s workflow, assign tasks to team members, and track the progress of projects by moving kanban cards from one column to the next.

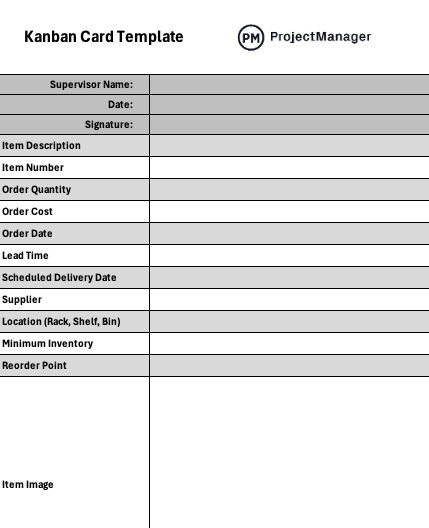

Kanban Card Template

This kanban card template for Excel can help you implement a 2-bin kanban inventory system for your organization. It allows you to enter all the information that you’ll need to know when reordering inventory items, such as order quantity, price per unit, lead time, scheduled delivery date and much more.

Kanban System Examples

The best way to learn how to implement the kanban methodology in an organization is to look at some kanban board examples. Here are some examples of how kanban boards are used in different industries.

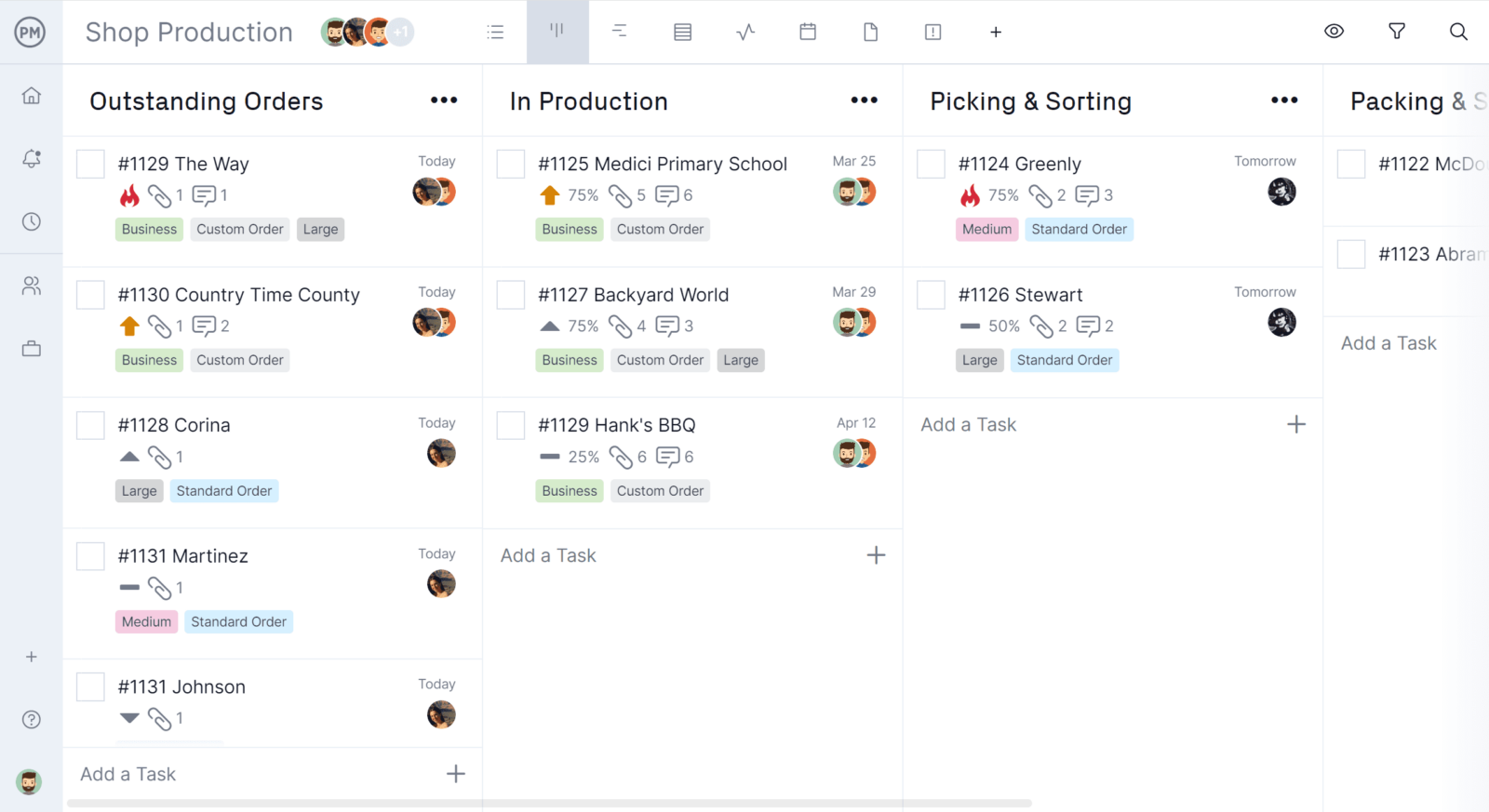

Manufacturing Kanban System Example

This kanban board shows the status of various sales orders that a manufacturing company works on simultaneously. In this kanban workflow, the manufacturer adds each customer order to the outstanding orders column and moves them across the kanban columns as they go through the production and order fulfillment process.

This kanban board example has been created with ProjectManager, so it allows manufacturers to use kanban cards to track the cost of production of each order, estimate completion time, delivery due dates, priority levels, specifications and other details.

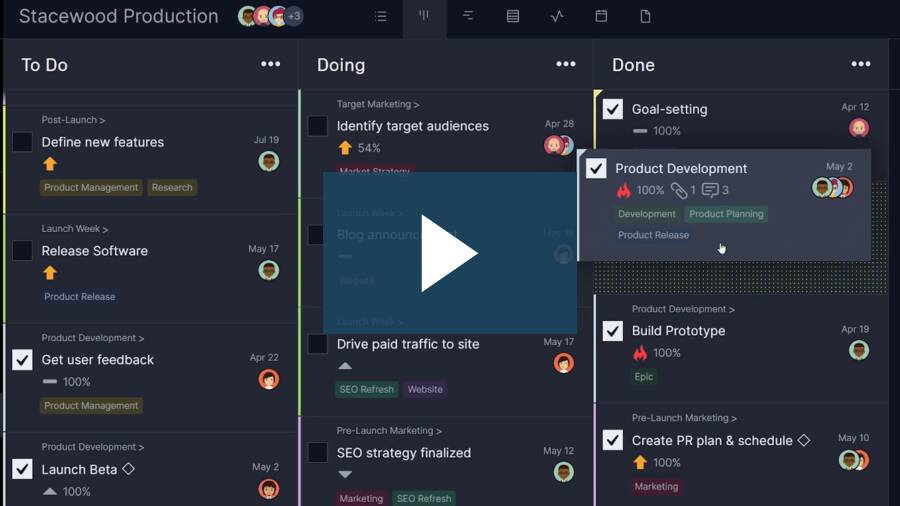

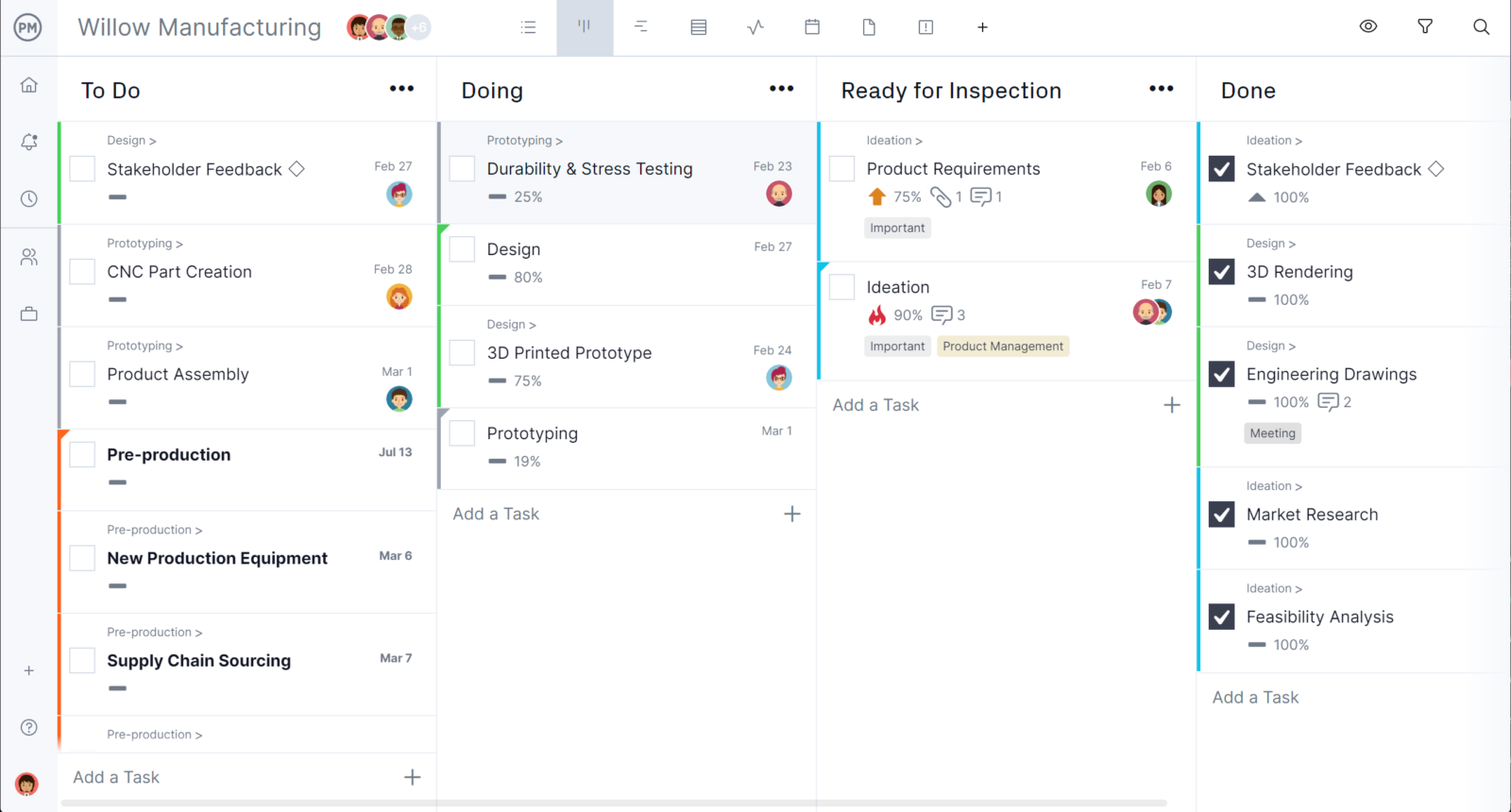

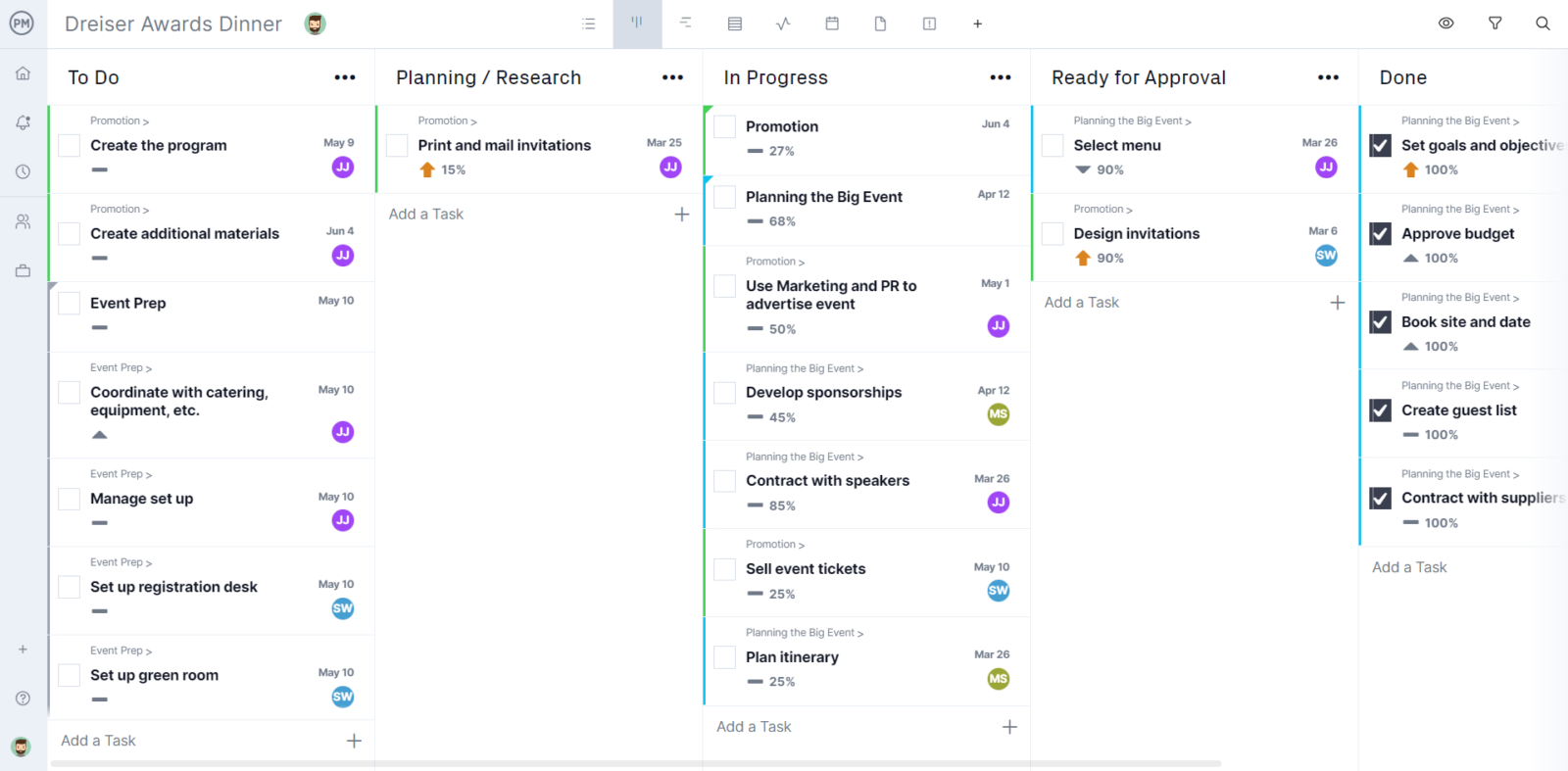

Product Development Kanban System Example

This kanban board shows all the different tasks that various teams in a manufacturing company are currently working on for the development of various products, such as durability testing, prototyping or market research.

There are four columns in this kanban board: “to do,” “doing,” “ready for inspection” and “done.” This is designed to track the tasks that are currently in progress, which of them are ready to be inspected by supervisors and those that have been completed.

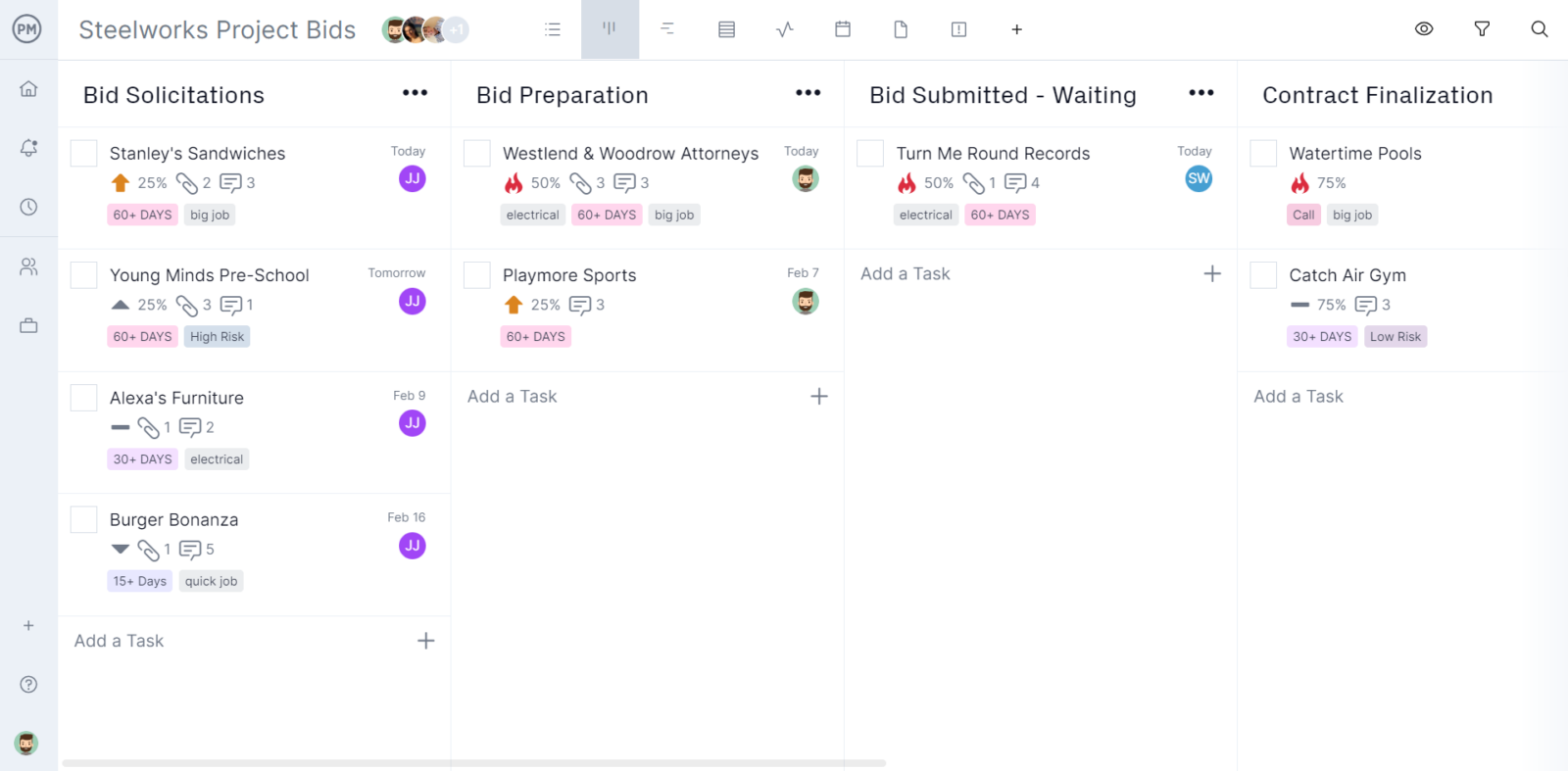

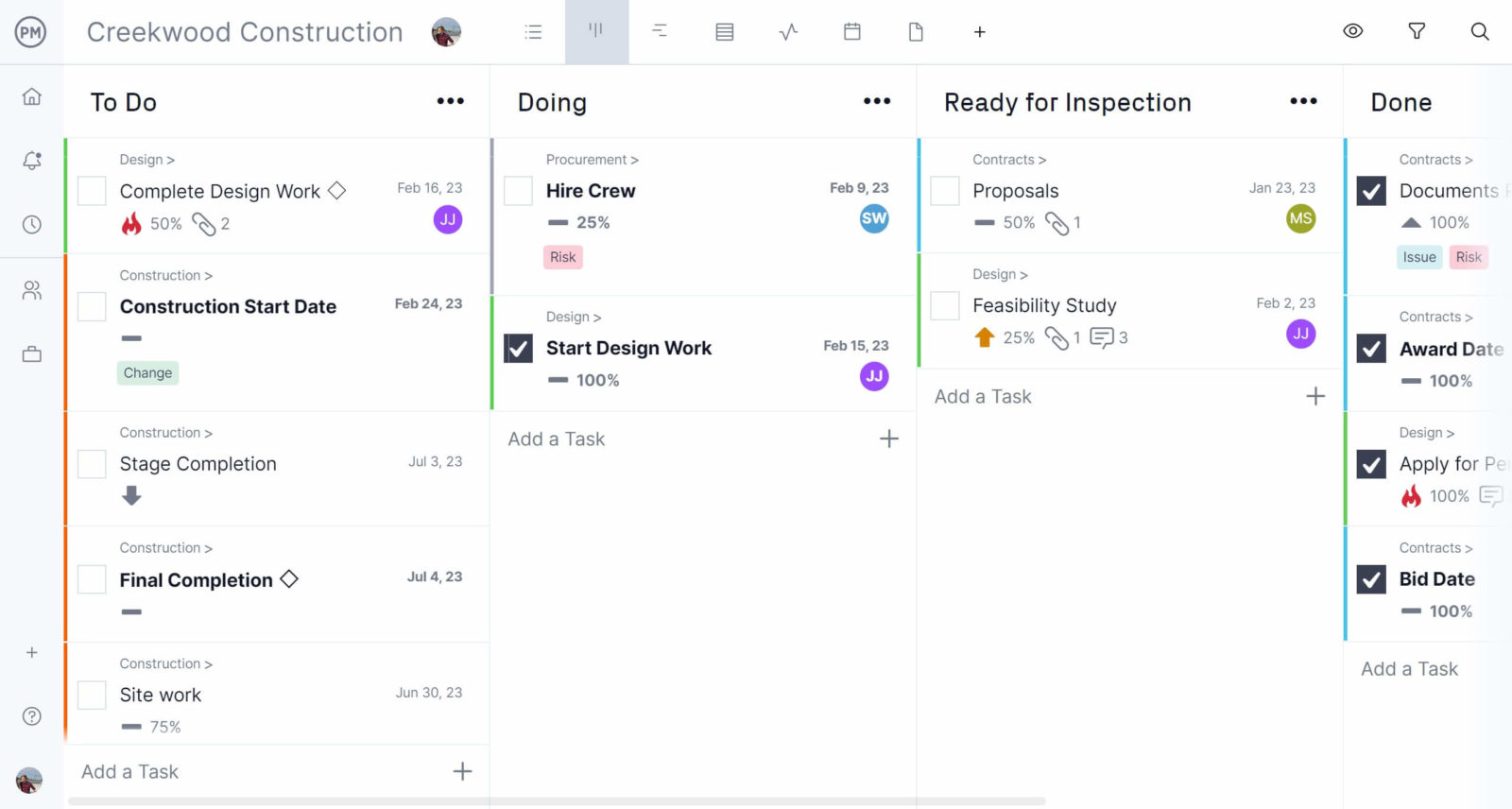

Construction Kanban System Example

This kanban board helps construction firms manage the construction bids they submit to private and public tenders so they can get awarded construction contracts. Each kanban card represents a bid and there are various steps in this process.

When the construction firm gets a bid solicitation document from a project owner, such as a request for proposal (RFP) or invitation for bid (IFB), a kanban card is created and placed in the “bid solicitations” column.

The next step is to prepare a bid as a response. Move the kanban card from column to column as it goes through the process, ending in the “contract finalization” column once the bid has been approved. This is only one of many applications for kanban boards in construction.

Construction firms, contractors and subcontractors can also use kanban boards to manage the daily tasks at the construction site, create punch lists for the post-construction phase or manage the construction planning phase.

With a general idea of what a kanban board is and how it works, next, let’s review elements of kanban methodology used when implementing a kanban system for an organization.

Kanban Principles

Before we learn about kanban boards, kanban cards and WIP limits, let’s learn the principles of the kanban methodology.

- Start with what you’re doing now: The first step when implementing kanban is to focus on what the organization is currently doing. Don’t change your process immediately, but use kanban to visualize your current workflow and begin making improvements.

- Changes occur organically over time and shouldn’t be rushed: One of the key aspects of kanban is the notion of continuous improvement, which consists of making small, incremental changes based on careful observation of workflows instead of making radical changes.

- Respect current roles and responsibilities: Implementing the kanban methodology doesn’t require any change in the organizational structure of teams. Changes in roles and responsibilities might come as the continuous improvement process advances but aren’t part of the kanban methodology.

- Encourage leadership from everyone: Kanban promotes a collaborative atmosphere where team members can suggest improvement opportunities to help keep the mandate of continuous improvement for maximizing efficiency.

Kanban Practices

The following kanban practices help teams ensure the above principles are followed when implementing the kanban methodology.

- Visualize workflow, whether through a physical board or kanban software

- Limit work-in-progress to keep teams executing tasks quickly

- Manage and improve workflow by observing work and resolving bottlenecks.

- Be explicit with process policies: define and share them

- Have feedback loops, such as review stages, to deliver the end product to the customer as quickly as possible

- Be collaborative and experimental to always push for improvement

Once you know what the practices are and how to use them, you’ll be able to use them in project management.

Get your free

Kanban Board Template

Use this free Kanban Board Template for Excel to manage your projects better.

Kanban Metrics

The term kanban metrics refers to the key performance indicators (KPIs) that are used in the kanban methodology to measure the productivity of workflows and processes. There are four main kanban metrics: lead time, cycle time, throughput and work-in-progress or WIP.

Kanban Lead Time

Lead time is a kanban metric that measures how long it takes for tasks to be completed within a kanban workflow. To calculate the lead time for a kanban workflow, measure the time elapsed from the moment a kanban card is created to when it’s completed. That is when it’s gone through each of its workflow stages, represented by the kanban board columns.

Repeat the same process for all tasks to determine the average lead time of the kanban system. Monitoring the lead time can help keep track of a team’s productivity and identify bottlenecks or opportunities for improving the workflow. Workflows are more efficient when unnecessary steps are eliminated or resources better allocated.

Kanban Cycle Time

The cycle time of a kanban system is similar to its lead time. This kanban metric differs from lead time as it ignores the time when a kanban card is created and focuses on measuring the time that a team member spends actively working on a task from start to finish. A high cycle time means team members are not completing their work within the expected timeline, for whatever reason.

It’s important to measure both the lead time and cycle time of your kanban system. A discrepancy between the two can help identify inefficiencies. For example, a high lead time and low cycle time can mean a team is understaffed. Tasks are spending too much time on the kanban board, but they’re generally completed promptly once a team member is assigned to them.

Kanban Throughput

The throughput of a kanban system measures the number of completed work items at a specific time, such as a day, week or month. This allows for the monitoring of a team’s productivity and helps in understanding its resource capacity.

By constantly monitoring the throughput of a kanban system it becomes clear what a team can achieve within a given time. This helps allocate resources more efficiently, accurately estimate the duration of tasks and creates realistic project schedules.

Kanban Work-in-progress (WIP)

Work in progress is a simple yet important kanban metric. It measures the total number of tasks in progress at one time or all the tasks that aren’t part of the product backlog but aren’t completed.

The work-in-progress metric helps measure the progress of a project and it can also be used for managing your team’s workload as it helps you identify overallocated team members and determine whether the team is prioritizing their workload correctly.

Having too much work-in-progress is one of the things that project managers need to avoid when implementing a kanban system. That’s because if a team works on fewer tasks at a time more resources can be allocated, such as people and tools, to complete the tasks faster. For this reason, some kanban boards have a feature called kanban WIP limits.

Kanban WIP Limits

Kanban WIP limits can set the maximum number of work items placed within the different workflow stages or columns of the kanban board at a time.

By using kanban WIP limits, manufacturing, product development, construction and agile software development teams can concentrate on only those crucial tasks and get their work done faster.

What Is Kanban Software?

Naturally, to execute a kanban system you need some sort of a kanban board, but it doesn’t necessarily need a digital platform. The structure is simple and could be applied with a wall and sticky notes in columns. However, the right kanban software can help project managers and their teams visualize their workflow and collaborate even better.

Kanban software facilitates the continuous improvement of the production process. That’s because it has added task management features, such as tracking, WIP limits, reporting functionality, forecasting and more.

Web-based kanban software further adds efficiencies for kanban teams by being accessible from everywhere and at any time. This is ideal for remote or distributed teams, keeping them in communication and fostering collaboration. Also, with online project management software, updates are instant and changes go live immediately. This adds to efficiencies as the project manager and teams can see the actual progress of the workflow.

To learn more about kanban software, watch the short video below.

Must-Have Kanban Software Features

Kanban software varies in terms of what tools it offers, so when you’re looking to use one be sure it has these features.

Work How You Want

No two projects are exactly the same, nor are the teams that execute them. Kanban boards need to reflect this flexibility with customizable columns. Add as many as you need and name them whatever you want.

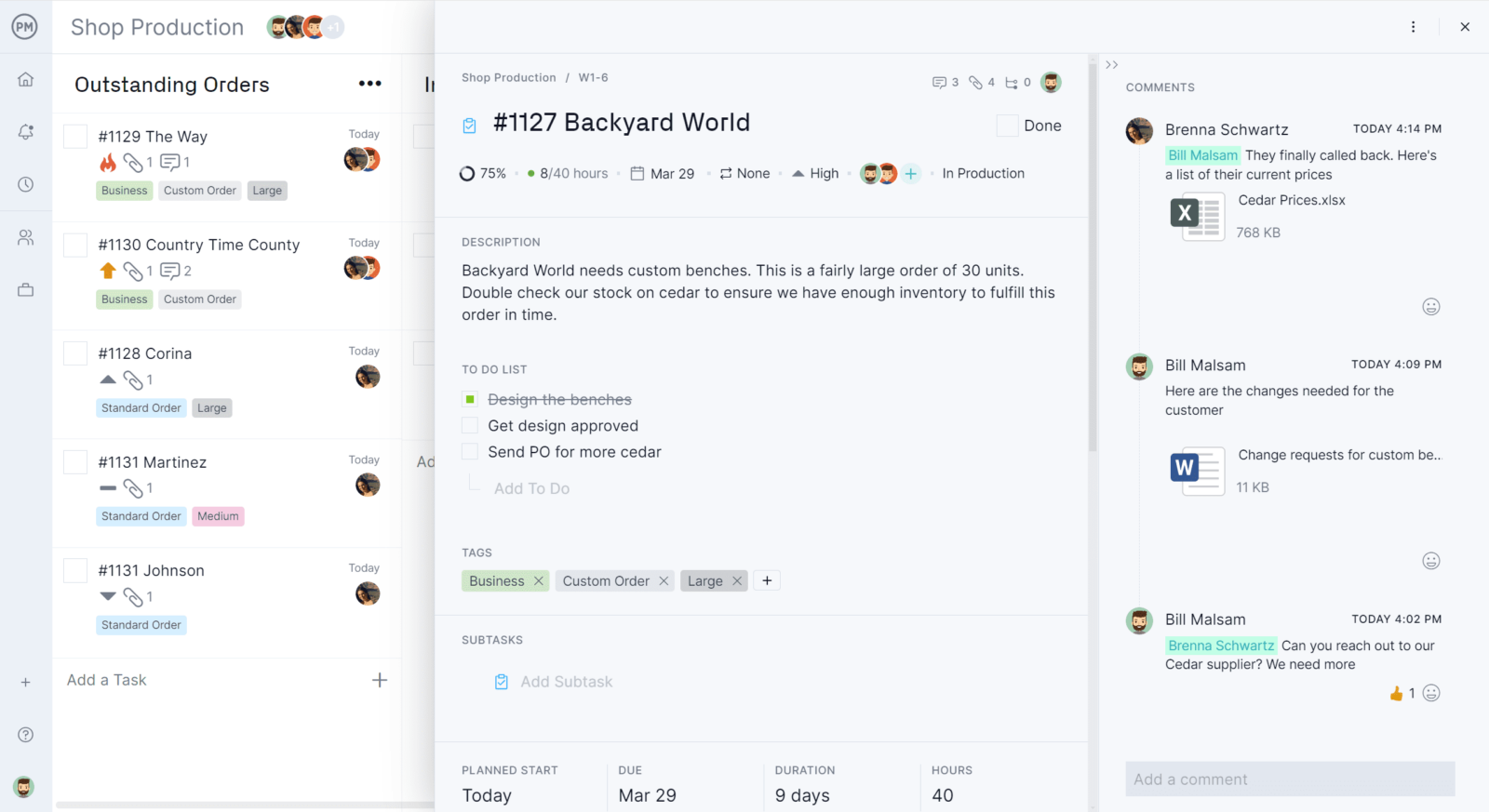

Get Teams Working Together

Connecting your team, wherever they might be, boosts productivity. Sharing kanban boards and being able to add comments to cards gives your team a platform to collaborate. Get a real-time tool that’ll notify you whenever there’s an update to the task, too.

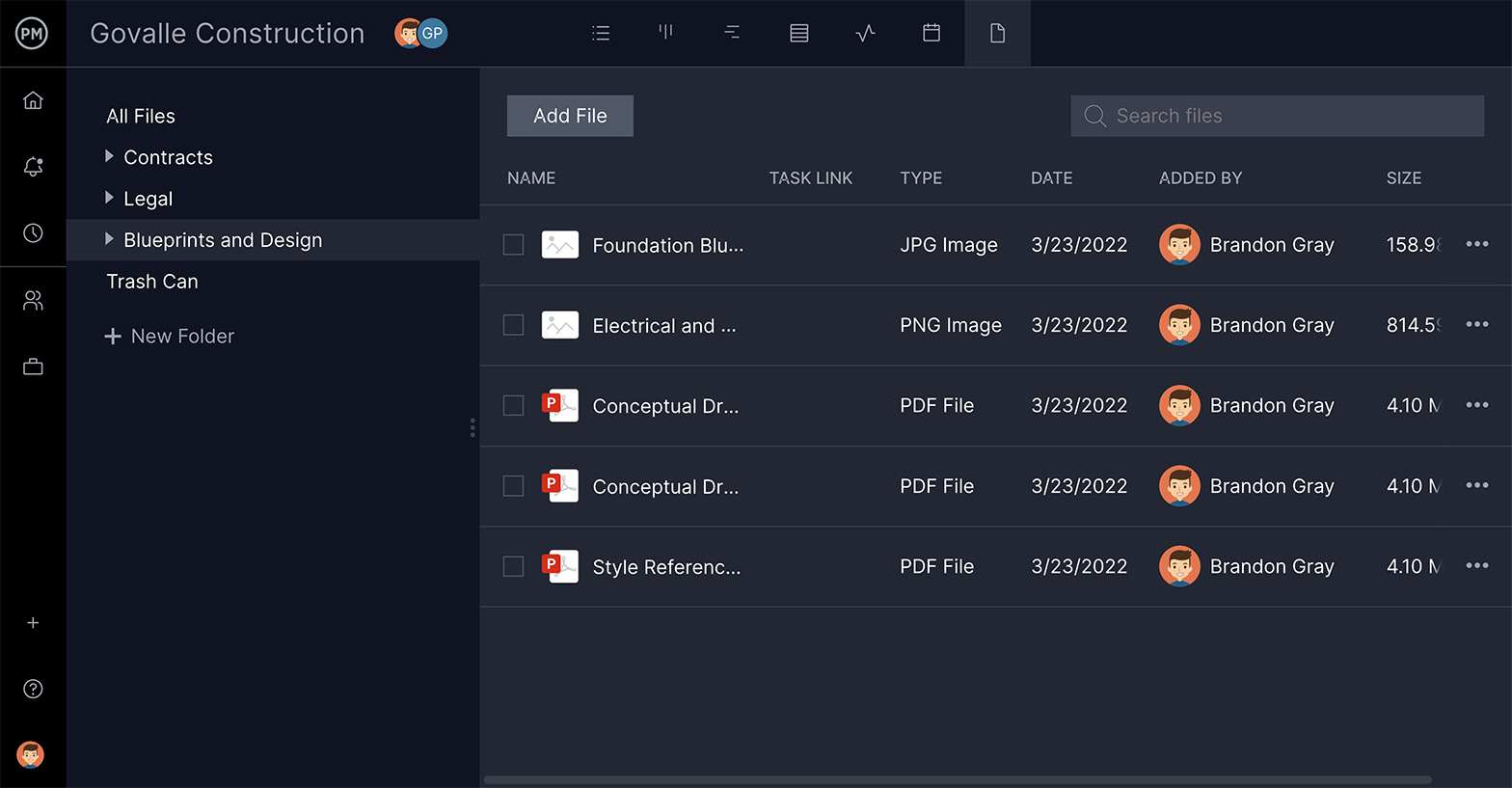

Hold All Important Documents in One Place

Giving direction helps teams execute their tasks better. Being able to add files and images directly to a kanban card makes those directions more clear. In fact, having unlimited file storage to keep all your project documents in one place is ideal.

Sort Through Your Task With Ease

Projects have many tasks and finding the one you want can be an ordeal. If you tag your kanban cards for priority, type of work, team, etc., filtering the tasks will bring up what you want to see without having to dig through every file on the tool.

View Project Status Anytime

Managers need to monitor their project to keep them on track. Kanban boards offer transparency into production, but a dashboard calculates other project metrics. It shows what you’re spending, the overall health of the project, variance, time and much more.

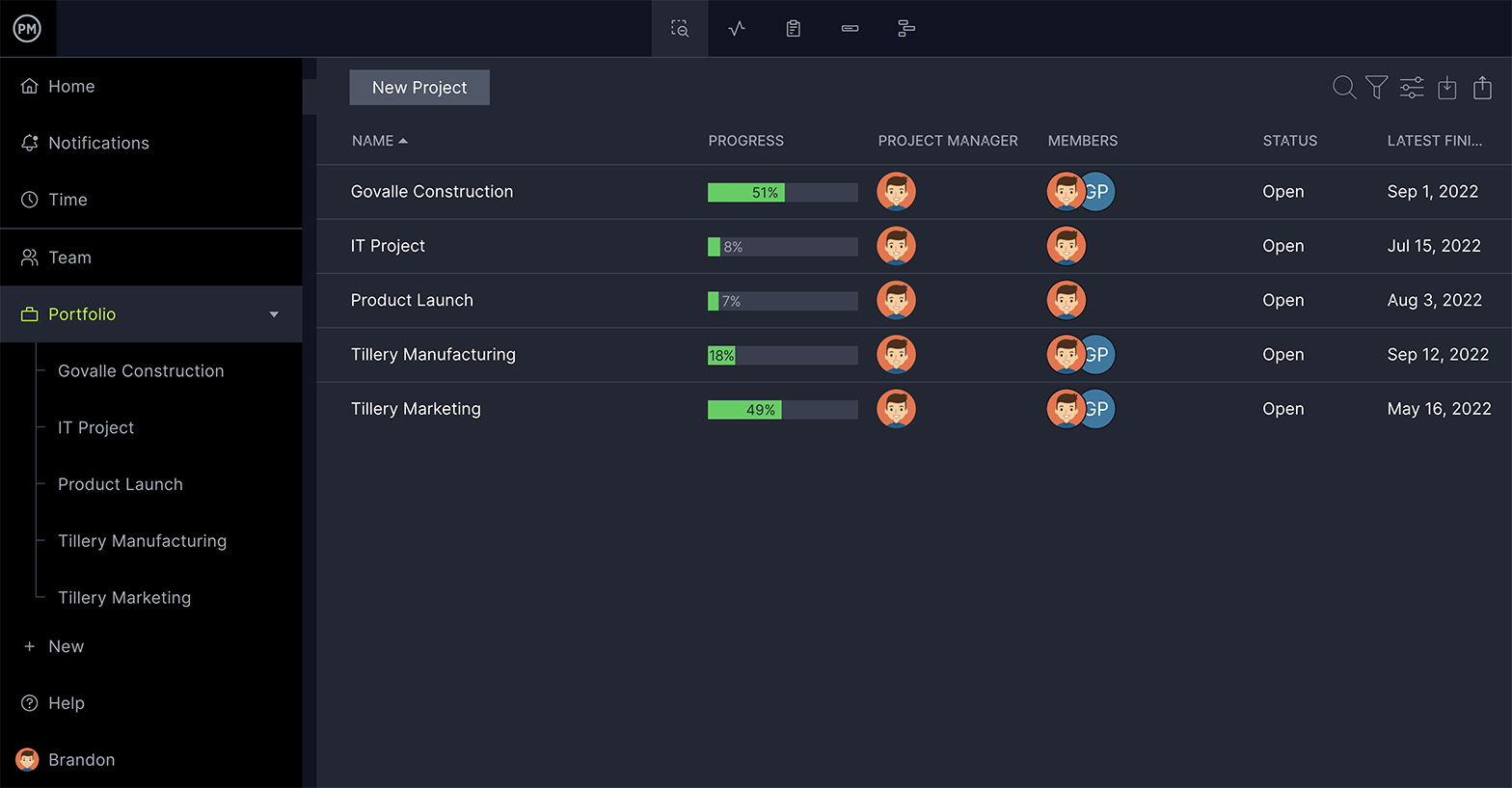

Make as Many Projects as You Like

Some kanban software can only manage one project at a time—more will cost you. But you want to have a tool that can handle as many projects as you need. Even one project is really more like a bunch of sub-projects and you need a kanban tool that can accommodate them all.

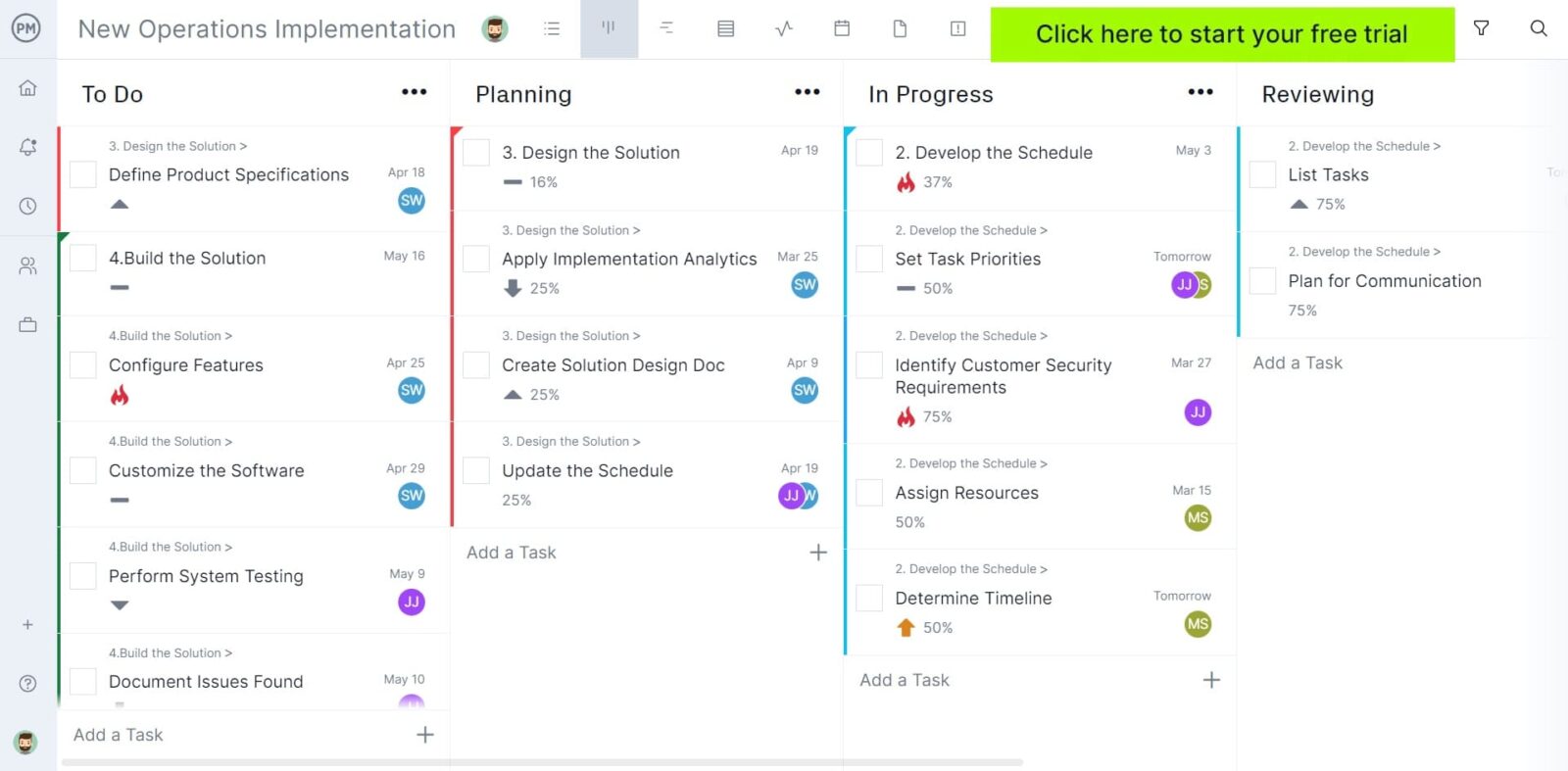

How to Use ProjectManager to Implement the Kanban Methodology

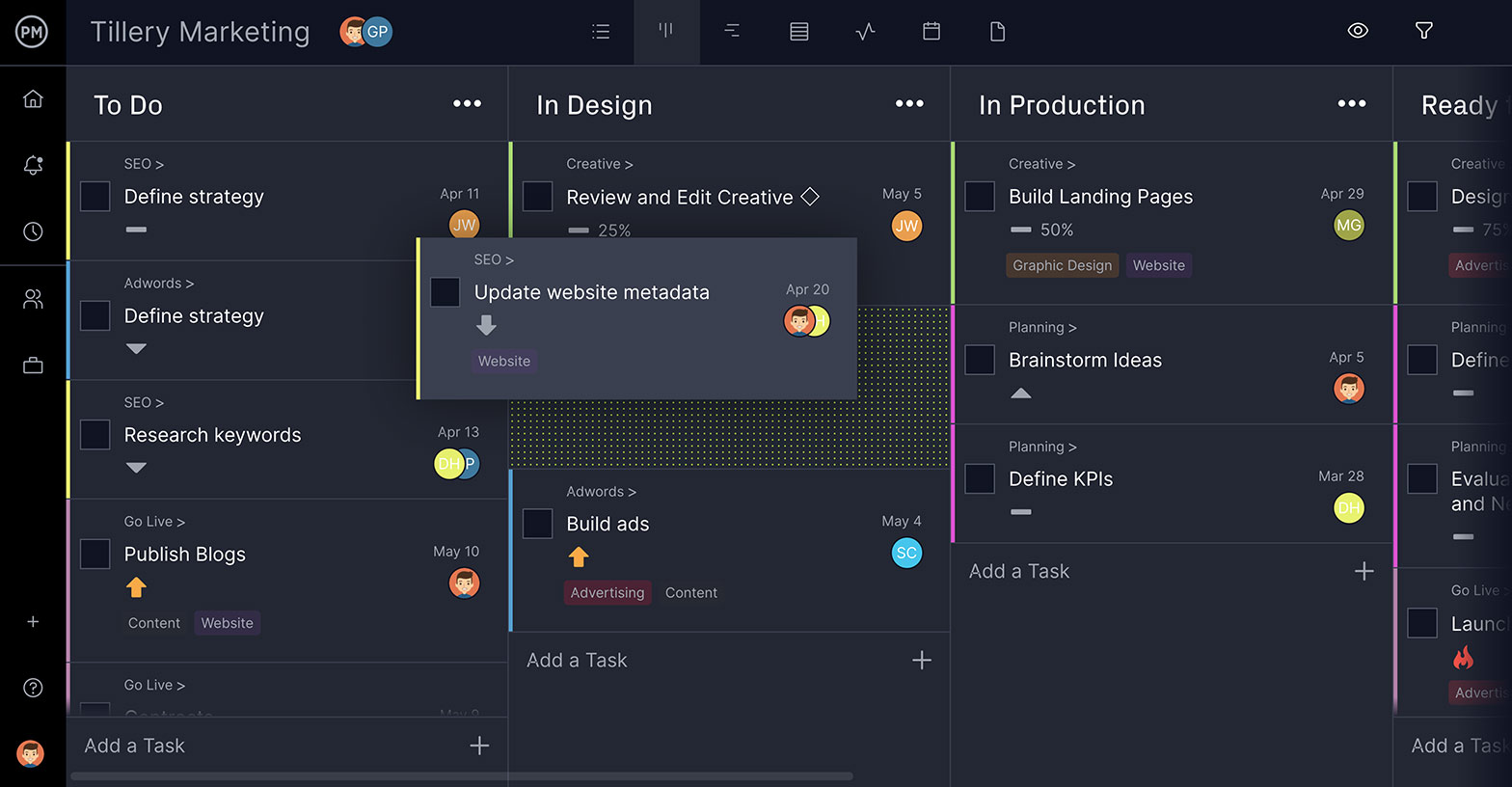

ProjectManager, online project management software, is an ideal kanban software for project managers and teams. It visualizes workflow and has task management features that make assigning and executing tasks as simple as a keystroke.

To use the kanban view with ProjectManager, start a free 30-day trial. Then, upload your task list, or create a new project. Follow this step-by-step guide below to get started with ProjectManager’s free kanban board.

1. Add Columns to Your Kanban Board

The traditional kanban process has three columns: to do, doing and done. But you can title the columns whatever suits your workflow. There can be as many columns as needed to visualize the various task management stages. Essentially, this is a flow from assigned to executing to complete.

2. Add Kanban Cards

Now, beneath the to-do column, add the individual tasks or work items to the kanban board. Your kanban cards should have a descriptive title so they can be easily understood. Remember to define WIP limits to control how many kanban cards are being executed at the same time.

3. Add Description and Assign Task

Write a description on your kanban cards to provide instructions for the task. The kanban card can then be assigned to one or more team members, and supporting documents or images can be attached to it. These kanban cards will move to the work-in-progress column as they’re being executed and to the done column when complete.

4. Collaborate on Tasks

You can open up your task right from the kanban view. Throughout the process, comments can be added at the task level, and team members will get email notifications when an @ is added before their name. This keeps everyone on the same page and enables real-time team collaboration.

Benefits of Kanban

The benefits of the kanban methodology are myriad. Here are some of the main advantages of using kanban for manufacturing, software development and project management.

- Kanban Helps Teams Control Their Workflow and Prioritize Work: The kanban method helps teams control the amount of work that’s being executed by setting work-in-progress limits. This is one of the main advantages of the kanban method. By focusing on the most important tasks, teams can complete projects faster.

- Kanban Promotes Team Collaboration: As mentioned, the kanban methodology offers a visual means to manage workflow. The kanban board puts the whole process on one page or screen so it’s easy to see who’s working on what and where that falls in the project cycle. This helps team members better collaborate.

- Kanban Is Compatible With Agile, Scrum and Waterfall Projects: As stated, kanban is a versatile method that can be used in conjunction with project management methodologies such as agile, scrum and waterfall. This makes it valuable for software development, manufacturing and project teams.

- Kanban Facilitates the Continuous Delivery of Products: A kanban system keeps work moving without interruption which helps teams achieve a continuous delivery of products. Kanban facilitates the smooth movement of workflow, avoiding bottlenecks and overloaded teams with too many assignments at once.

History of the Kanban Methodology

Taiichi Ohno, an industrial engineer at Toyota in the 1940s, developed kanban. It was originally a task management system to execute lean manufacturing.

It was designed to improve the Toyota just-in-time (JIT) production system efficiency by limiting supplies and resources to what was needed for the immediate work items. Today, kanban boards are used in nearly every industry, most notably in agile software development.

The kanban method was created as a lean manufacturing tool to maximize production efficiency. Since then, it’s become a great task management tool for DevOps and agile teams and is used in different industries such as software development.

This is just a quick overview of some of the major events in the history of kanban. If you’d like to learn more, you can visit our blog for a deeper dive into this topic.

Kanban Training, Courses & Certifications

Kanban boards are a very intuitive tool that can be used by anyone, however, mastering the kanban methodology requires training.

Fortunately, various kanban training programs can help with understanding and managing a kanban system for organizations, which can improve a team’s work.

There are also kanban certification programs that can help advance a career in project management. Here are some of the most popular kanban training, courses and certifications.

- Agile Certified Practitioner (PMI-ACP) by the Project Management Institute (PMI)

- Professional Scrum with Kanban™ (PSK I) certification by Scrum.org

- MSI Kanban Certification by Management and Strategy Institute

- Certified Kanban Expert by Scrum Institute

Kanban FAQs

Here are some of the most frequently asked questions about the kanban methodology. We hope these answers are helpful.

What Does Kanban Mean?

The meaning of kanban in Japanese is “billboard” or “visual card,” which is a simple way to describe the visual approach to the kanban methodology for managing work in manufacturing, project management and software development.

When Should You Use Kanban?

As we learned above, kanban is a methodology that was first invented to improve existing manufacturing processes. Manufacturing organizations commonly adopt kanban to improve their efficiency and profitability by improving their operations. However, kanban might also be used for managing software development and other types of projects from scratch.

What Are Kanban Swimlanes?

Kanban swimlanes are horizontal lanes that go across kanban columns and help separate different work items, activities, teams, services, etc. They’re especially useful for large kanban boards with many kanban cards.

What Is a Kanban Inventory Management System?

The term kanban inventory management simply refers to using a kanban pull system to manage the production process of an organization. This means that all production inventory is only purchased upon receiving an order from a customer, as in just-in-time (JIT), lean or make-to-order (MTO) manufacturing models.

The main benefit of using a kanban inventory system is that excess inventory doesn’t have to be stored, which adds to the operational costs of a business and reduces its profitability.

What Is the Kanban Pull System?

The kanban pull system is a make-to-order (MTO) manufacturing technique that minimizes the waste of raw materials by using production inventory only when there’s a customer order, as opposed to manufacturing products based on market demand forecasts. This is known as make-to-stock (MTS) manufacturing.

Here are some main benefits of using the kanban pull system for manufacturing.

- Reduces production costs, such as labor, warehousing, materials and maintenance

- Ensures there’s enough resource capacity whenever a customer places a purchase order

- Allows for the customization of products to meet the specific requirements of each customer

- Keeps teams focused on a purchase or sales order at a time, which can positively impact lead times and product quality

What Is the Kanban Methodology Commonly Used For?

Now that we’ve learned how kanban works, let’s go through its most common applications: project management, software development and manufacturing.

Kanban in Project Management

Kanban is a great project management methodology mainly because it allows project managers to break down the scope of a project and helps teams easily understand what they’re working on by simply observing what’s in the kanban boards.

In addition, kanban principles and practices ensure the team constantly improves their processes so that they can work collaboratively and efficiently for successful project delivery.

Most project management teams use kanban software which is equipped with tools such as workflow automation, collaboration features and other project management tools to help teams better implement the kanban methodology.

Kanban in Software Development

Kanban is a popular project management approach for agile software development because kanban and agile have principles and practices that are compatible. While agile works best when the final goal isn’t set and adapts as the project progresses, kanban works to reduce waste and eliminate those activities that aren’t adding value.

Agile software development teams work in short sprints, usually no more than two weeks. Kanban strives for short cycle times as well so it can deliver its features faster. Both are tethered to constant communication to enhance collaboration.

One of the main reasons why agile teams love kanban is that kanban boards are a great visual tool to manage the user stories of software development projects while providing a project overview.

Kanban in Manufacturing

A kanban system can manage the whole value chain of any lean manufacturing production process. That is, from the supplier to the end customer and all points in between.

It does so by helping manufacturers with production planning, inventory control and task management throughout the production cycle from ordering parts and components to creating the production schedule.

Kanban in Lean Manufacturing

To use kanban for lean manufacturing, kanban cannot be an isolated tool but must be used throughout the entire value chain. That’s necessary as lean project management’s continuous improvement principle requires constantly removing waste from processes while keeping resources balanced with the needs of production planning.

For example, bottlenecks slow down production because there’s too little supply or too much supply for the resources allocated to the process. Kanban helps manage production inventory by using a pull system to control workflow. That pull system consists of adding more work items to the kanban board, only when other tasks have been completed.

How Does Kanban Differ From Agile, Scrum and Waterfall?

Kanban is one of many project management frameworks and can be easily mistaken for other similar methods. Here’s how kanban compares to agile, scrum and waterfall.

Kanban vs. Agile

Agile is a software development approach that can be implemented through a kanban system. Practically speaking, agile defines the guidelines that software engineering teams will follow as they use a kanban framework.

For example, agile requires teams to plan their work through sprints, which are short iterations of work that must be completed until a software product is delivered. Software development teams will plan those sprints by using kanban boards. So, ultimately kanban is the means for applying the agile methodology.

Agile project management teams enjoy using this system due to its ease of use, visual interface and ability to instantly see what everyone is working on. It also provides visibility into task progress and whether a specific task is holding up the project.

Kanban vs. Scrum

Just like kanban, scrum is a framework used to implement agile project management in an organization. So, how do kanban and scrum get along?

Many teams that are using scrum in projects find kanban a powerful tool. Scrum and kanban can work together, especially to visualize workflow. But they also complement each other, as both focus on process and the elimination of waste.

There are differences, however: roles and responsibilities in a kanban system are not pre-defined like they are in scrum teams. Kanban isn’t scrum. It’s visual and scrum is iterative.

However, kanban can be customized to fit in a scrum framework to manage projects, workflow and processes. There’s even a project management methodology called scrumban that mixes elements of both scrum and kanban.

Kanban vs. Waterfall

Like agile, waterfall is a larger project management methodology that can use kanban as a work management framework. However, unlike agile, waterfall is best suited for projects that are completed linearly, instead of using an iterative planning process. Waterfall teams will use kanban boards differently than agile teams.

While kanban helps agile teams plan and manage sprints, waterfall teams use kanban boards to manage their daily work instead of being used as a planning tool.

Kanban Resources

Start your free 30-day trial

Deliver faster, collaborate better, innovate more effectively — without the high prices and months-long implementation and extensive training required by other products.

Start free trial